Welcome to the future of glass technology with our vacuum glazed windows and doors.

What is Vacuum Insulated Glass?

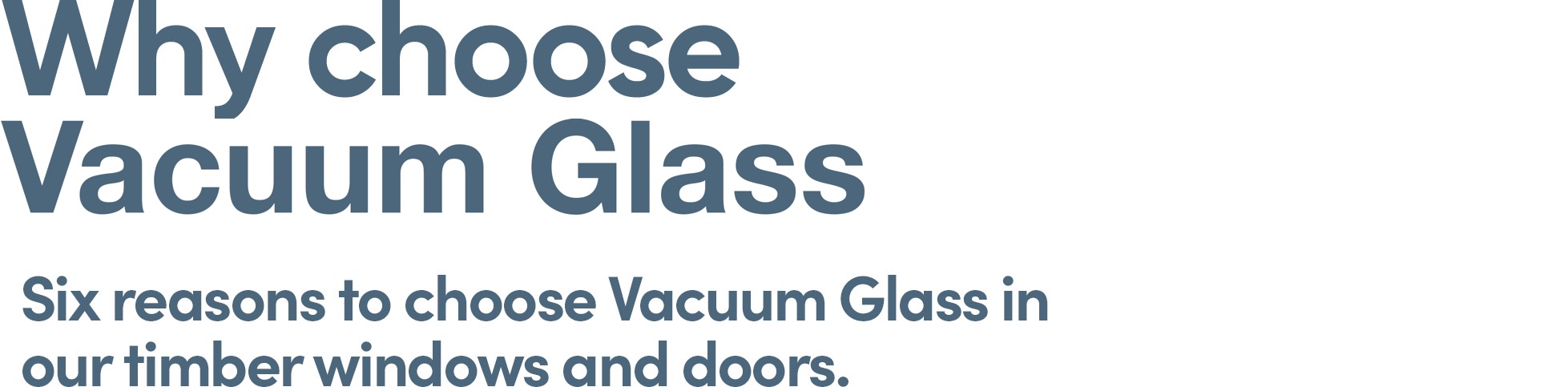

Vacuum Insulated Glass (aka ‘Vacuum Glass’) boasts the slender profile of single glazing while delivering unparalleled thermal and acoustic performance that outperforms even triple glazing. Vacuum glass is the most thermally and acoustically efficient glazing on the market today. Thinner and lighter than traditional double glazing, vacuum glass is also more durable and attractive, lending itself beautifully to conservation sliding sash and casement windows.

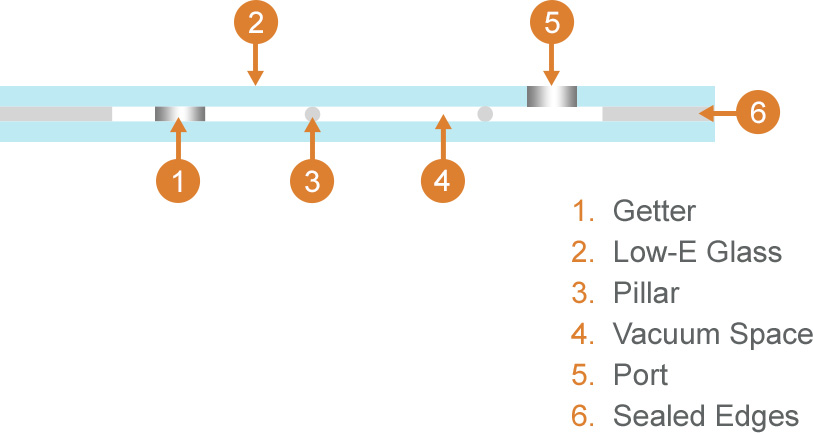

Developed in Japan by Panasonic™ and further developed by LandVac™, our vacuum glazing is constructed from two sheets of toughened glass bonded together, leaving a 0.3mm vacuum gap, air is then evacuated, the unit sealed, and advanced technology is used to maintain the vacuum. Under the atmospheric pressure of the vacuum, barely visible micro-pillars are used to keep the two panes of glass apart.

1. Aesthetics

1. Aesthetics

Ultra-thin profiles make vacuum insulated glass perfect for retaining the aesthetics of single glazed heritage buildings, there is no internal double glazing spacer bar, and no visual disturbance from the double reflection associated with traditional double glazing. Vacuum glass seamlessly mimics the appearance of single glazing, making it an ideal solution for listed buildings and conservation areas.

2. Comfort

2. Comfort

Vacuum glazing gives you a warmer home in winter and a cooler one in summer. The vacuum chamber blocks thermal transmission, providing thermal insulation performance which is 2 – 4 times more efficient than double or triple glazing and between 6 – 10 times better than single glazing.

3. Silence

3. Silence

For a quieter more peaceful home, vacuum insulated glass offers leading noise reduction without using heavy and chunky triple glazing or expensive laminated acoustic glazing.

4. Safety

4. Safety

We use vacuum glass made by LandVac™ who have pioneered the use of toughened (tempered) glass in vacuum insulated glazing. All LandVac™ glass is toughened and certified to British Standards for thermally toughened safety glass.

5. Durability

5. Durability

LandVac™ vacuum insulated glass boasts a robust bonded construction, utilising toughened glass throughout, ensuring a stable product with a lifespan surpassing that of double or triple glazing. Additionally, it comes with a market-leading 15-year warranty.

6. Sustainability

6. Sustainability

LandVac™ vacuum glass has a centre-pane U-value of just 0.4W/m2K which allows for lower energy consumption, reducing CO2 emissions and bills. Vacuum glass is lightweight, uses less materials, is fully recyclable, and does not use any energy intensive Nobel gases such as Argon, Krypton, or Xenon.

Exceptional timber windows and doors, now with vacuum glass

We’ve created two new product ranges with vacuum glass. The ‘Heritage’ Range is perfect for Listed Properties or those in Conservation Areas, and The ‘PassivHaus™’ Range is designed for super high performance needs.

The ‘Vacuum Heritage’ Range

The ‘Vacuum Heritage’ Range

The Vacuum Heritage range brings 21st-century technology to heritage buildings, achieving unparalleled thermal efficiency not possible with traditional slimline glazing products. Specifically designed for heritage and conservation homes, it provides a genuine solution to balancing aesthetics and energy efficiency when replacing windows in listed and historically important buildings.

Our Vacuum Heritage windows replicates the appearance of traditional single-glazed windows from the past while delivering exceptional performance. The unique combination of Sashed traditional joinery profiles and LandVac™ Enhance Heritage 8.3mm vacuum glazing offers the best of all worlds: the appearance of traditional single-glazed windows with industry leading levels of thermal and acoustic insulation, which also benefit from low maintenance, durability, and sustainability.

The precision detailing of our traditional Heritage Range of windows and doors includes slender 17mm glazing bars, faithfully replicating the appearance of a traditional putty-glazed window. The slim 8.3mm-wide LandVac™ Enhance Heritage glass aligns with the preferences of conservation officers for traditional single-glazed windows. With a mere 0.3mm cavity, it eliminates discernible double reflection, meeting the stringent requirements of conservation officers. Notably, LandVac™ Enhance Heritage units have received approval for installation on several Grade II listed properties across London and the southeast of England.

The ‘PassivHaus™’ Range

The ‘PassivHaus™’ Range

Looking for industry leading insulation from your windows? Look no further than the PassivHaus™ range from Sashed. Our PassivHaus™ range of timber windows and doors are crafted to adhere to the rigorous standards of The Passive House Institute, this range of products represents the pinnacle in our window innovation. Meticulously designed and built to be ‘the best’ in thermal efficiency, featuring a proprietary sealed triple glazed unit and a vacuum cavity. Sashed’s PassivHaus™ range is a testament to pushing the boundaries of excellence and innovation.

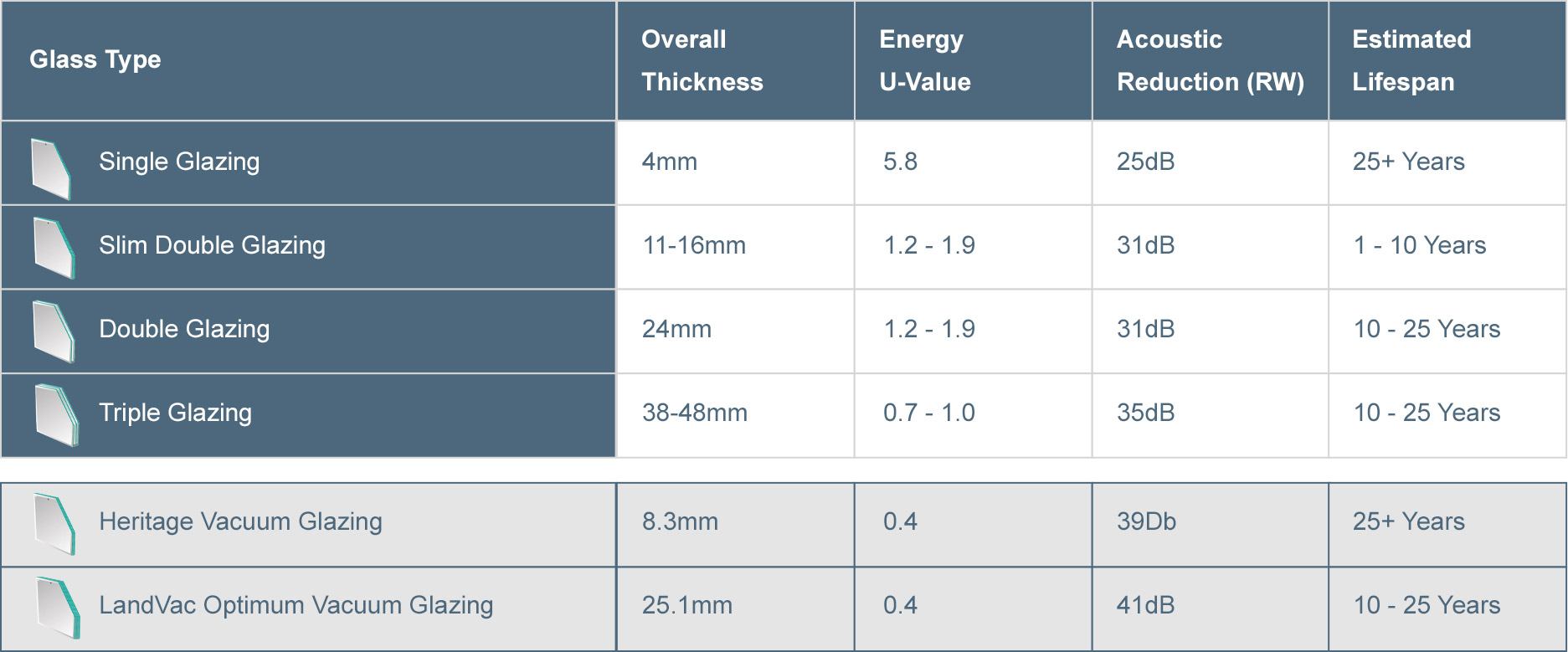

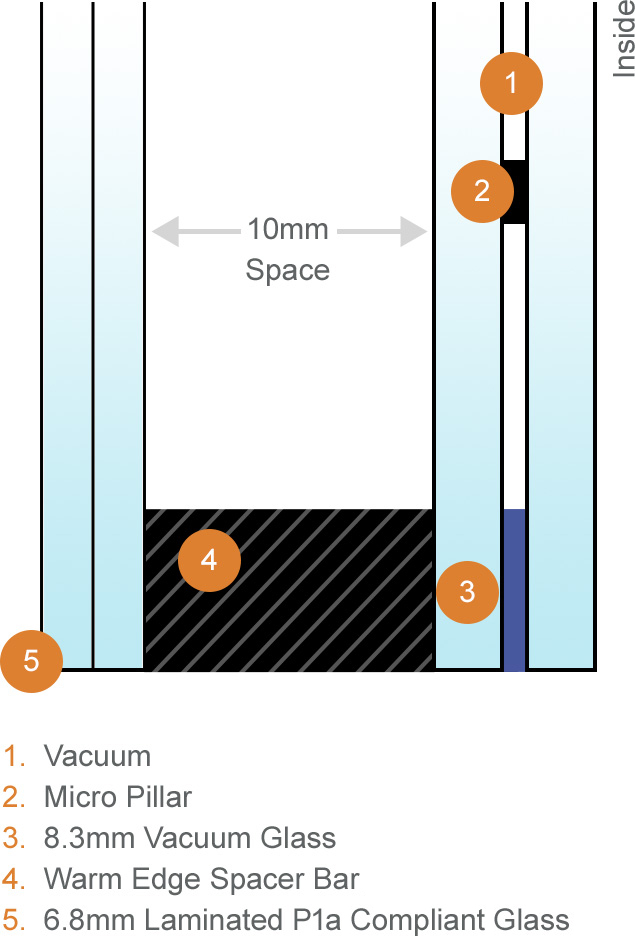

LandVac™ Optimum is a proprietary glazing unit with an inbuilt vacuum cavity. Think traditional double glazing with Vacuum Insulated Glass on the inside and Laminated Glass on the outside, separated using a traditional double glazing bar spacer. LandVac™ Optimum comprising 8.3mm Vacuum Glass, 10mm space, and 6.8mm laminated outer pane. Incorporating warm-edge spacer technology reduces the U-Value of the overall window from 1.13W/m²K to just 0.79W/m²K in both our PassivHaus casement and our PassivHaus sliding sash profiles.

At 25.1mm overall thickness LandVac™ Optimum can be use where traditional double glazing units have previously been used. The use of thinner 25.1mm glazing enables more traditional window dimensions and better aesthetics compared to the bulky frames required to accommodate triple glazing, often associated with PassivHaus™ windows.

Request a quote now ?

Here Comes The Science Bit

Here Comes The Science Bit

Heat transfer by conduction and convection relies on particles colliding and in turn transferring energy, but in a vacuum there are no particles, heat transfer can only occur by radiation thus reducing the overall amount of heat transfer. Similarly, sound waves travel by vibrating through the particles of a medium, such as air or water, from a source to a receiver. In a vacuum, there is no medium for heat and sound to travel so the vacuum chamber blocks thermal and acoustic transmission.

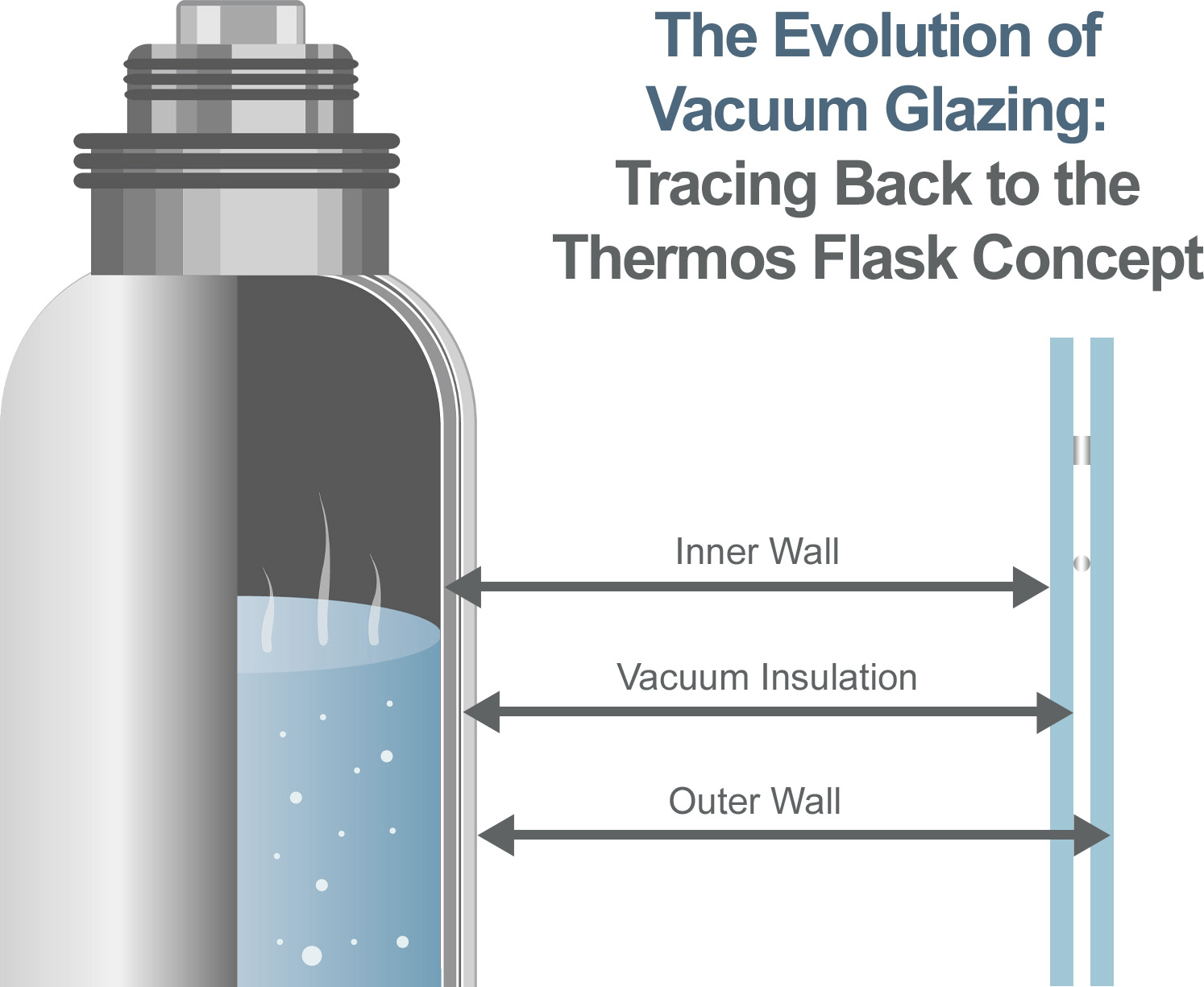

The development of vacuum glazing finds its roots in the concept of the thermos flask. The vacuum Dewar flask, is a creation of Cambridge University professor James Dewar in 1892. This flask consists of a double-layer glass container, the air between the glass layers is then evacuated, creating a vacuum.

James Dewar identified the fundamental principles of vacuum insulation based on his flask, these principles are still in use today and form the foundation of the exceptional thermal insulation performance of vacuum glazing, distinguishing it from traditional double or triple insulated glazing.

Top performing glazing from the market leader in vacuum glass

Top performing glazing from the market leader in vacuum glass

Sashed have chosen LandVac™ as our preferred supplier of vacuum insulated glass.

LandGlass Technology Co, Ltd the company behind LandVac’s™ market leading vacuum insulted glass, have an R&D team consisting of nearly one hundred dedicated engineers and scientists. LandGlass have devoted eight years of challenging work to the development of fully toughened (tempered) vacuum insulated glass, breaking the myth that vacuum glass can′t be tempered.

Unlike other vacuum glass on the market today LandVac™ uses two pieces of toughened glass either side of the vacuum giving it safety, reliability and strength which means it requires 8 to 10 times fewer micro-pillars.

We use LandVac™ Enhance Heritage as standard which has no visible evacuation port and no circular getters.

Interested discovering more about our Vacuum Insulated Glass ranges?

Are you a homeowner, self-builder, interior designer, or architect looking to for vacuum glass for a listed building, house renovation, new build, or commercial project?

We would love to discuss your project and help create a the right solution for your needs!

Make an enquiry using this form or email hello@sashed.com

Vacuum Glass Frequently Asked Questions

Although trusted for many years in commercial applications vacuum glass is relatively new to the UK domestic market compared to double glazing. These FAQs cover basic aspects of vacuum glass, but if you have more specific questions please get in touch with us.

Why does Sashed use LandGlass LandVac™ and not other types of vacuum glass?

We use LandVac™ because it is the market leader, and is superior in a number of important ways:

It is toughened as standard. This is really critical, to comply with building regulations where protection against falling is required (eg in doors and in most sash windows).

The thermal performance is fantastic, with a centre pane U-value just 0.4 W/m2K.

LandVac™ has approximately 8 times fewer micro pillars than other types of vacuum glass and the pillars themselves are more subtle semi transparent grey in colour.

LandVac™ is available in larger sizes (up to 1.5m x 2.5m).

The acoustic performance is extremely good.

Do you offer vacuum glass with a frosted, obscured, leaded or colour finish?

Vacuum glass units are currently only commercially available in standard clear glass. However, we can integrate vacuum glass with other types of glass to provide the complete range of glass options offered with traditional double glazing, forming a sealed unit. For instance, we can incorporate vacuum glass on the interior side of the frame and obscured glass on the exterior, mirroring the configuration of a traditional double glazing unit. Alternatively, we can apply a frosted film to vacuum glass.

I’ve been approved for slimline double glazing can I change to vacuum glass?

If you have already obtained planning approval for slimline double glazing, you cannot switch to vacuum glass, as the construction of vacuum glass and slimline glass differs. Technically, you would need to apply for a ‘variation of condition’ to your existing planning permission. Depending on your individual circumstances, it is likely that planners and conservation officers would view this variation favourably. In our experience, they actively prefer vacuum glass over slimline glazing. You should discuss your specific needs with us so that we can provide better advice on the appropriate course of action.

Can I see plugs and getters?

We utilise LandVac™ Enhance Heritage as our standard, which features no visible evacuation port or circular getters. Instead, there is a smaller 3mm getter line towards the edge of the unit. Additionally, we incorporate a deeper rebate in the timber of the sash. This design ensures that both the plugs and getters are concealed behind the timber, thereby preserving the aesthetics without compromise.

Is vacuum glass more expensive than other types of glass?

Vacuum glass tends to be more expensive than traditional double glazing but more cost effective than slimline double glazing. Keep in mind that the initial cost of vacuum glass may be offset by potential long-term benefits, such as improved energy efficiency and insulation, which could result in lower heating and cooling costs over the lifespan of the product.

What is the lifespan of vacuum glass?

In general, high-quality vacuum glass units are designed to have a long lifespan, exceeding that of traditional double-glazed windows. Many manufacturers provide warranties for their vacuum glass products, which can range from 10 to 25 years or more. As technology and manufacturing processes continue to advance, it’s possible that the lifespan of vacuum glass could improve over time.

What is the maintenance requirement for vacuum glass?

Maintenance is generally low; regular cleaning is usually sufficient to keep vacuum glass in good condition.

Can vacuum glass be used in extreme weather conditions?

Yes, vacuum glass is designed to perform well in various weather conditions, providing effective insulation in both hot and cold climates.

Customer Projects

Customer Projects Gallery

Gallery Our Showroom

Our Showroom Listed Buildings

Listed Buildings